VOC EMISSION CHAMBER - N-Wissen

Main menu:

VOC EMISSION CHAMBER

Applications:

The VOC test chamber provides standard testing environment to determine the VOC emission rate and emission characteristics of interior decoration materials and products.

Based on the test report, we can:

- Determine the impact of environment variables on the VOC emission rate and emission characteristics.

- Classify the level of products and materials according to the emission characteristics.

- Develop and adjust indoor air pollution models.

- Evaluate the IAQ (Indoor air quality) according to the pollution data and test report.

As being a significant means of VOC emission test, the VOC emission chamber finds a wide application in interior decoration, office furniture, engineered wood, carpets, plastics, leather, textile, toys and more.

Configuration:

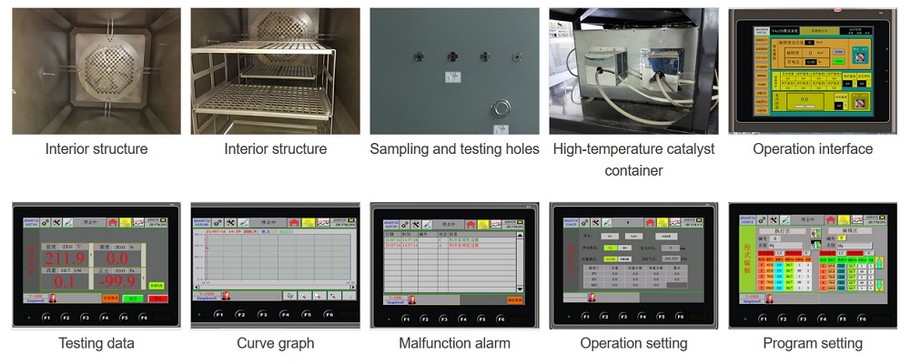

- Interior structure

- Sampling and testing holes (the hole number can be customized)

- High-temperature catalyst container

- Control system (many languages are available) includes: Operation Interface; Testing Data; Curve Graph; Malfunction Alarm; Operation Setting; Program Setting; etc

Technical Specifications:

| Model: | V-50 | V-100 | V-250 | V-500 | V-1000A | V-1000B | V-2000 |

Temperature Range: | 10 to 40°C; high temperature cleaning 250°C; Temperature Fluctuation: ±0.3°C; Temperature Deviation: ±0.5 °C | ||||||

Humidity Range: | 40 to 70% R.H. (20°C to 30°C) Humidity Fluctuation: ±2.5%R.H; Humidity Deviation: ±3% | ||||||

Ambient Conditions: | Environmental temperature: 5 to 35°C; Environmental humidity ≤ 90% R.H No pollutant source in the surrounding environment TVOC ≤500µg/m³ | ||||||

Air Exchange Rate: | 0.2 to 2/h ±5% (Optional 0.2 to 3/h ±5%) | ||||||

Air Velocity | 0.1m/s to 0.3m/s | ||||||

Dimensions (W × D × H) (cm): | 56 x 30 x 30 | 63 x 40 x 40 | 70 x 60 x 60 | 102 x 70 x 70 | 158 x 80 x 80 | 91 x 100 x 110 | 200 x 110 x 90 |

| Power Supply | AC 380V/50HZ three-phase power supply 4/5 wiring system | ||||||

Starting power: | 5kw | 6kw | 8kw | 10kw | 15kw | 15kw | 20kw |

Operating power: | 3kw | 3.4kw | 5kw | 6kw | 7kw | 7kw | 9kw |

| Rate of Recovery: | Formaldehyde, octanol, 4 phenyl Cyclohexene, dodecane and tetradecane have a recovery rate larger than 80% | ||||||

Clean Air System: | Standard configuration | ||||||

Testing Method:

- The air is first processed by compressor to remove solid particles, formaldehyde and volatile organic compounds, and then enters into the test chamber.

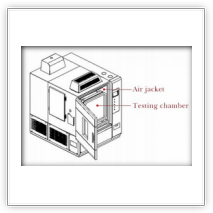

- The climate chamber is designed with an air jacket for conditioning the temperature in testing chamber.

- By adopting dew point method, the humidity of climate chamber is well regulated and controlled.

| Standards | Description | ||

ASTM D6007-02: | Standard Test Methods for Determination of Formaldehyde Concentration in air which are released from Wood Products with Small Scale Environmental Chamber. | ||

ENV717-1: | Environmental Chamber Method for Measurement of Formaldehyde Emission of Manmade Board. | ||

EN13419-1: | Determination of VOCs Release quantity of Building products Chapter One The Method for Releasing and Testing the Environmental Chamber. | ||

ASTM D5116-97 | Standard Guide for Determination of Organic Release from Interior Materials and Products with Small Scale Environmental Chamber | ||

ASTM D6330-98 | Standard Operation for Determination of VOCs (Excluding Formaldehyde) Release from Wooden Board with Small Environmental Chamber under Specified Test Conditions | ||

ASTM D6670-01 | Standard Operation for Determination of VOCs Release from Interior Materials and Products with Full Scale Environmental Chamber | ||

ASTM E1333-96 | Standard Test Methods for Determination of Formaldehyde Concentration and Release Rate in Gases Released from Wood Products with Large Scale Environmental Chamber | ||